It's time for a update.

Early last year I broke a set RX diff delrin bushings. By broke, i mean one was completely missing and the other was in about four or five pieces.

I decided to move forward with my 8.8 IRS rear. I bought a samberg 8.8 cradle and started teaching myself to TIG weld in prep for attaching the rear mounts.

This was after a week or so of practice. My skills have been progressing as this was about 1 month ago. Constructive feedback is welcome of course.

I called LPW to inquire about the flange thickness of their IRS girdle diff covers. They offered a good deal on a fubar'd cover they had laying around. They ate up the rear mount while machining and were willing to sell it cheap. After cutting the mount off and slightly modifying samberg's batwing mounts, it fits like a champ. I thought i had pics, I'll take and add some later.

I ordered a set of DSS 8.8/RX axles back in aprox 05 or 06 iirc. I believe Jim Lab's original measurements were incorrect as my shafts were .5 too short. The axles have been sitting around for years so i figured I'd end up eating the cost on a new set of shafts.

Ready to buy a new set, I called DSS and spoke with Frank and Tad. They told me to send in my short shafts, cobra inners, and rx outters. They sent the axles back completely assembled with new boots, powder coated shafts, etc. All I paid was shipping to their shop. Unreal customer service!

I decided while the rear is out to go ahead and resolve my cooling issues. The car runs cool enough to drive on the highway, but if caught in traffic it starts getting hot. It's a situation where I have to watch the coolant temp gauge and it just takes a lot of fun out of driving the car.

A larger radiator and higher flow fans are in order and I'm removing my hood latch to buy additional room.

BEFORE.

AFTER (the pvc pipe is a reference point for support brace. not only is there more room, air flow between the IC and radiator will be much better.)

I built a new frame rail support with 1" dom tubing and 3/16 plate. It's similar to MFerrari's solution.

This and the 8.8 mounts were my first welding "projects". I think they turned out decent.

I'm planning to rework the part so it extends down the frame rails for a second set of bolts as the radiator end tanks wont clear bolt heads.

With the support brace quasi finished, i started permanently re-mounting the intercooler. I cut and bent a few pieces of .09 sheet aluminum to make brackets. I made some bushings out of an old radiator hose to sit between the mounts and the frame. This was my second aluminum welding "project". I'm really happy with how it turned out.

I now have more room top and bottom to mount a radiator farther forward. (it's level, the pic is just a bit loff)

I ordered a custom Howe radiator with the same 24x15 core as MFerrari and Zbrown. Mine will be a 27x15 double pass with -16 AN fittings on the pass side.

I'm still waiting for it to arrive, no pics yet.

I bought a couple Summit -16 hose ends for mock up.

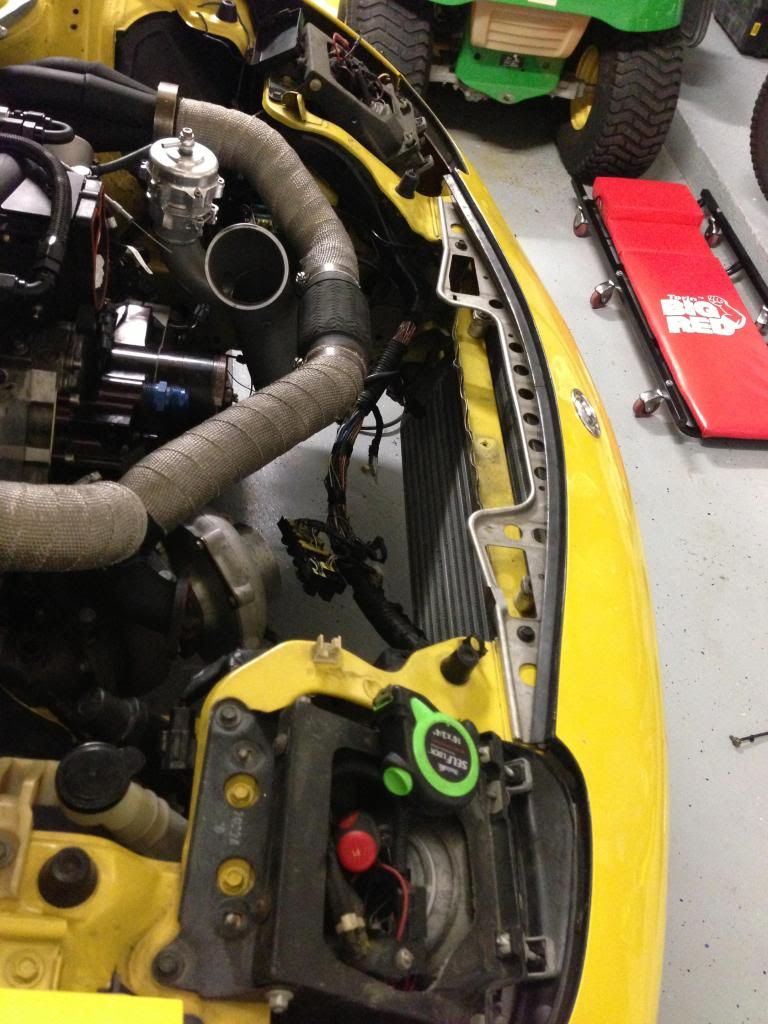

My water pump outlet is too tight for a 90, but a 45 clears. The radiator hose will need a thermal sleeve for sure. (Look at the finish on my cross over after removing the old wrap. yuck.)

Another clearance obstacle I have is my 50mm innovative wastegate, It sites over 7" high and the adjustment screw actually started wearing a hole in my aluminum radiator shroud. My new radiator will sit farther forward, but between the thicker core and larger fans it will have the same wg clearance issue. I decided to get a new more compact wastegate. This of coarse means modifying the cross over pipe for a new flange and sending it back out to jet hot. ......This sort of snow balled into swapping out my on-center turbo for a 7675 CEA with .96 hotside. I figure now is the time to do it while reworking re-coating stuff.

I'm also thinking about selling my Aeromotive A1000 and pump controller. A set of Bosche 044's will more or less be a wash cost wise and resolve my fuel supply limitations.

Somehow i ended up with this too. so yea, that's about all for now.