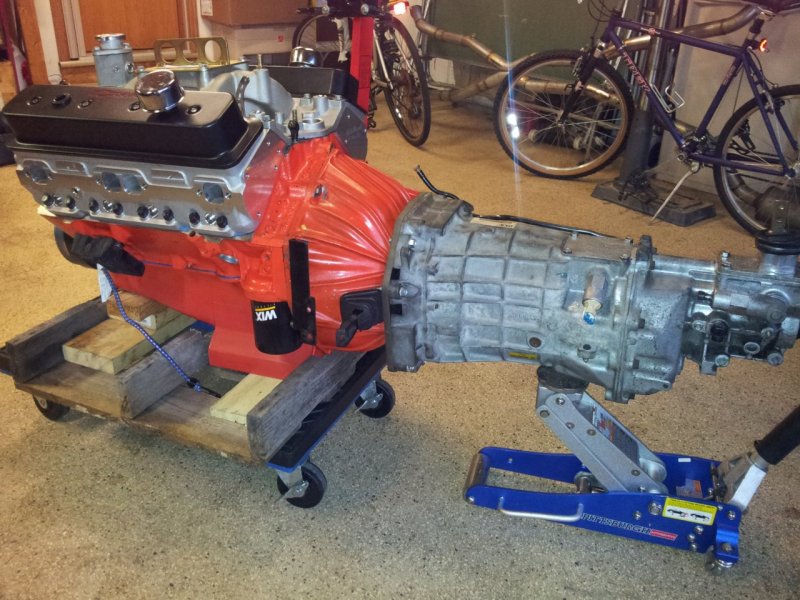

Got the T56 installed. Plus new heads.

The T5 held up fairly well all things considered. About 60 runs at GLD and countless

showing off on the street.

About 2 months ago I was having my usual fun. Pulling out of a parking lot from a stop

light drifting, banging gears and smoking tires. Just as I was going into third the whole

car felt like it lifted off the ground with a loud bang. No more forward motion and the

transmission sounding like ball bearings rolling around in steel garbage can.

Yup, trans grenaded with flourish.

I was going to just purchase another T5 and call it a day. A few of you convinced me that I

need to go T56. I started looking for a T56 from an LT1 because that bolts right up to my

Gen1 bellhousing. Due to my 2 piece rear main seal I found that I would need to swap my

flywheel with a conversion flywheel that would allow this to work. That flywheel cost about

$550 dollars. Plus the cost of the trans which usually run around $1500 for a used LT1 T56

and a new clutch assembly to work with the conversion I started to change my mind.

Jordan pointed me to a transdapt plate that would allow me to use my current

clutch,flywheel and bellhousing setup with an LS1 T56.

The cost of the transdapt plate was $200. I sourced an LS1 T56 from LS1Tech out of Texas

for $1100 shipped.

So, back to the 6 speed route.

Before I blew the tranny, (wait, that doesn't sound right) Before the trans blew I was

having some issues with burning oil at cylinders 3 and 5. I figured the intake manifold

gaskets broke on me again. (it happened to me when the engine was a 355 right after I put

on the massaged Vortec heads) I was going to replace the gaskets but also decided to

replace the heads with Edelbrock Etec 200cc aluminum heads. (my current heads were iron

Vortec heads that have been completely reworked)

I finally got everything done this weekend except exhaust because my system was designed

around the T5 and it's trans brace. I have an appointment to have the exhaust system redone

Friday.

Here's the trans:

Pulling the motor and trans:

Chasing the threads for ARP headbolts:

The new heads:

Getting close:

Here's the Gen1 block 2 piece rear main seal:

Centerforce DF Clutch with 6 puck disc:

Bellhousing, TOB:

Transdapt plate to mount LS1 T56 to Gen1 SBC:

Fork with plate installed:

Bolting the Transdapt to Bellhousing:

LS1 T56 bolted to Transdapt. The Transdapt plate holds the TOB in place so there is no

issue with trying to get the TOB lined up.

If I need to pull the transmission at a future date then I just unbolt the 7 bolts and

Back in the car and bolted up. I had to use a special T56 trans brace manufactured by

Granny's Speed shop. Pretty much bolt the motor in, mount the brace to the trans.

Raise the trans into position and drill new holes for the brace. I aslo had to have my

driveshaft resized due to the extra length of the T56. I have my DS

work done by Machine Service in Waukesha. 1 day turn around. Pretty sweet!

With the T5 the shifter was way forward. I had to cut out a large hole to accommodate it.

With the T56 it now sits back in the stock position.

I cut out some sheet metal and covered the old hole. (I'm not using this shifter. I'm using

my Steeda handle from my Pro-5.0 shifter from the T5.