Surprise day of progress! I had to take the new truck in to get a couple things fixed plus the sprinkler people were coming to winterize, so I took a random day off and spent some time working on the car in between shenanigans. Since I decided to weld elbows onto the turbo compressors, I put a pause on wastegate mounting until the elbows are in place and I've finalized orientation. So let's actually depower the Miata rack.

Berg87 kindly sent me a tool he made to open the rack up along with a video showing which spots to modify. I couldn't find any other good info or writeups on an NC rack out there so his help was invaluable.

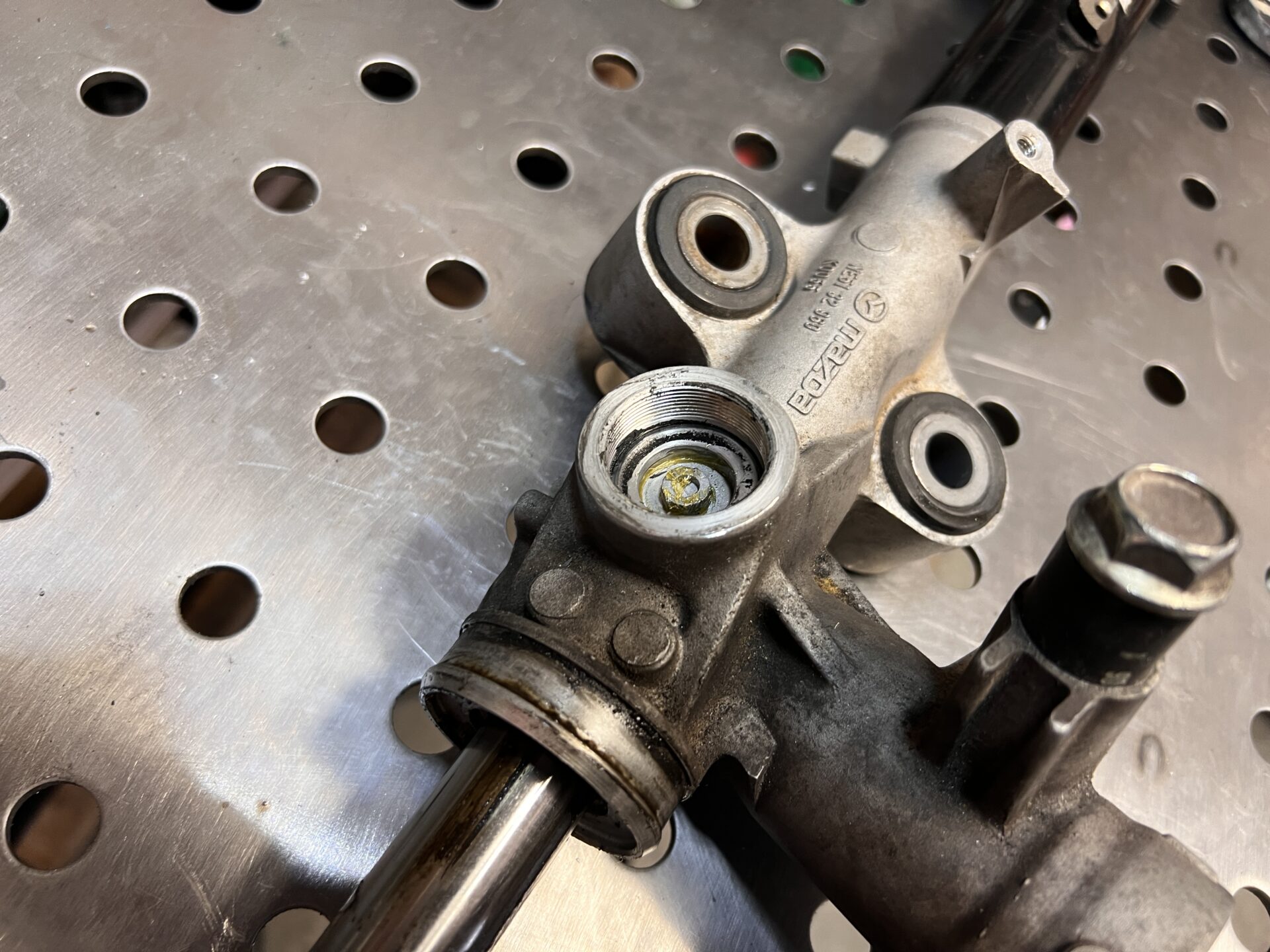

The lower pinion cover is a 36mm nut, I happened to have a 1-7/16" socket on hand that worked. There's a lock ring, a cap that can be removed with a 1/2" square ratchet drive, a spring, and a thrust washer.

Berg made a tool out of a nut to get at the internal hex of the upper pinion seal.

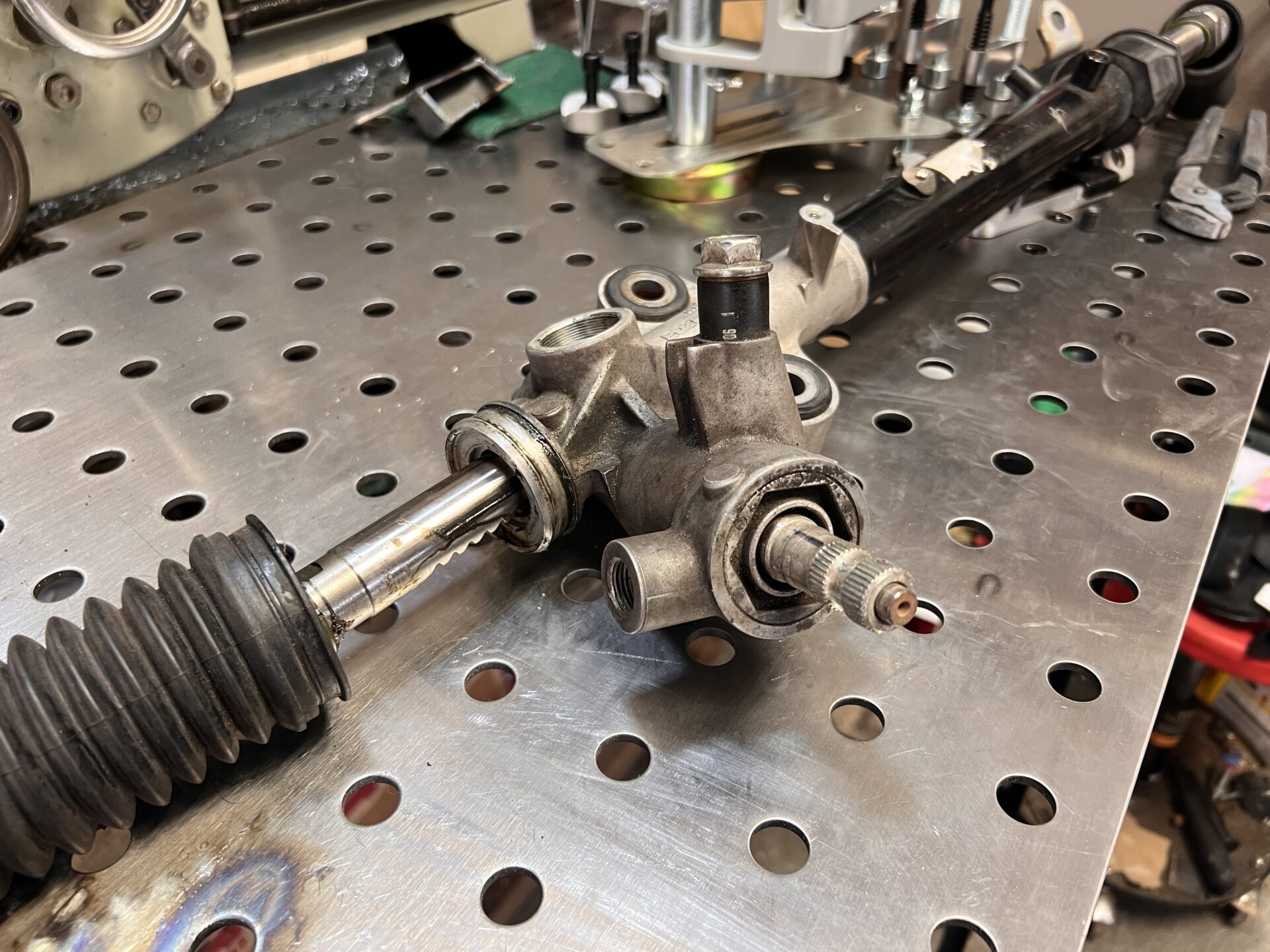

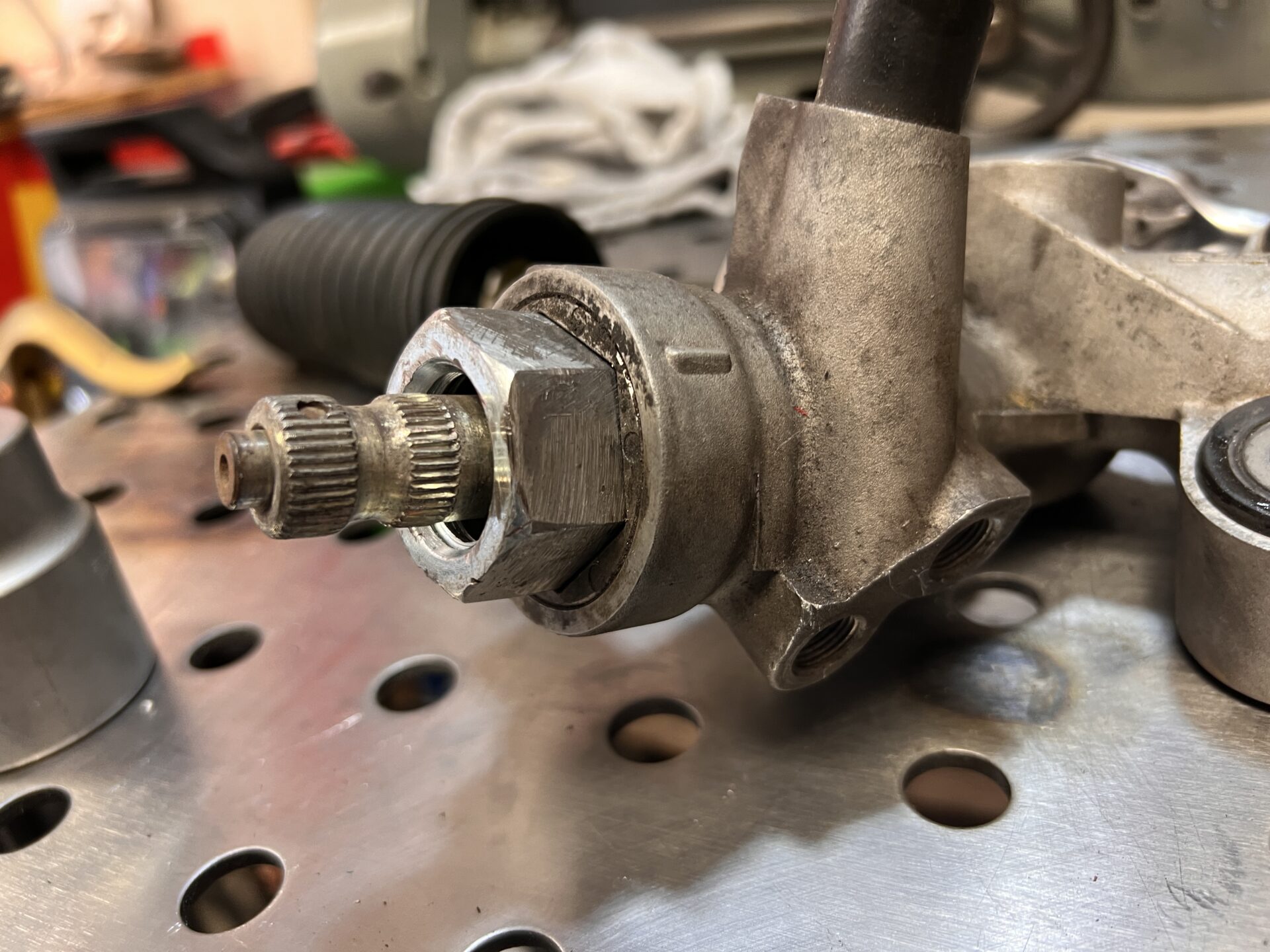

Then the pinion can be extracted and prepped for welding. There is a roller bearing with a threaded retention collar that gets removed. The pictured connection has a tiny bit of flex - this is what exposes the hydraulic ports when you turn the wheel to provide a path for pressurized fluid and provide assist. Some people don't weld this up for fear of warping the pinion, noting that the flex is minimal. The threads right at the point of welding make things interesting - the NA and NB racks don't have that. I'd have to be careful...

I ended up with a couple of high spots that I had to shave down so that I could thread the collar back on, but I got it. After:

Next up was removing the rack bar to remove the center seal. There's an aluminum hex cap opposite the pinion end that has to be removed to get the bar out. Unfortunately the steel tube of the rack is staked on the threads presumably so it doesn't back out. I don't have a good way to un-stake it, so I just backed the nut out, which took some effort and probably flattened the aluminum threads a little bit. A replacement cap is only $25, if I have any trouble getting this one back in I'll probably just grab a new one.

I don't know if there's a better way to drill or grind out the staked portion without messing up the threads or the rack's seal, maybe there is. You can see it at about 7 o'clock.

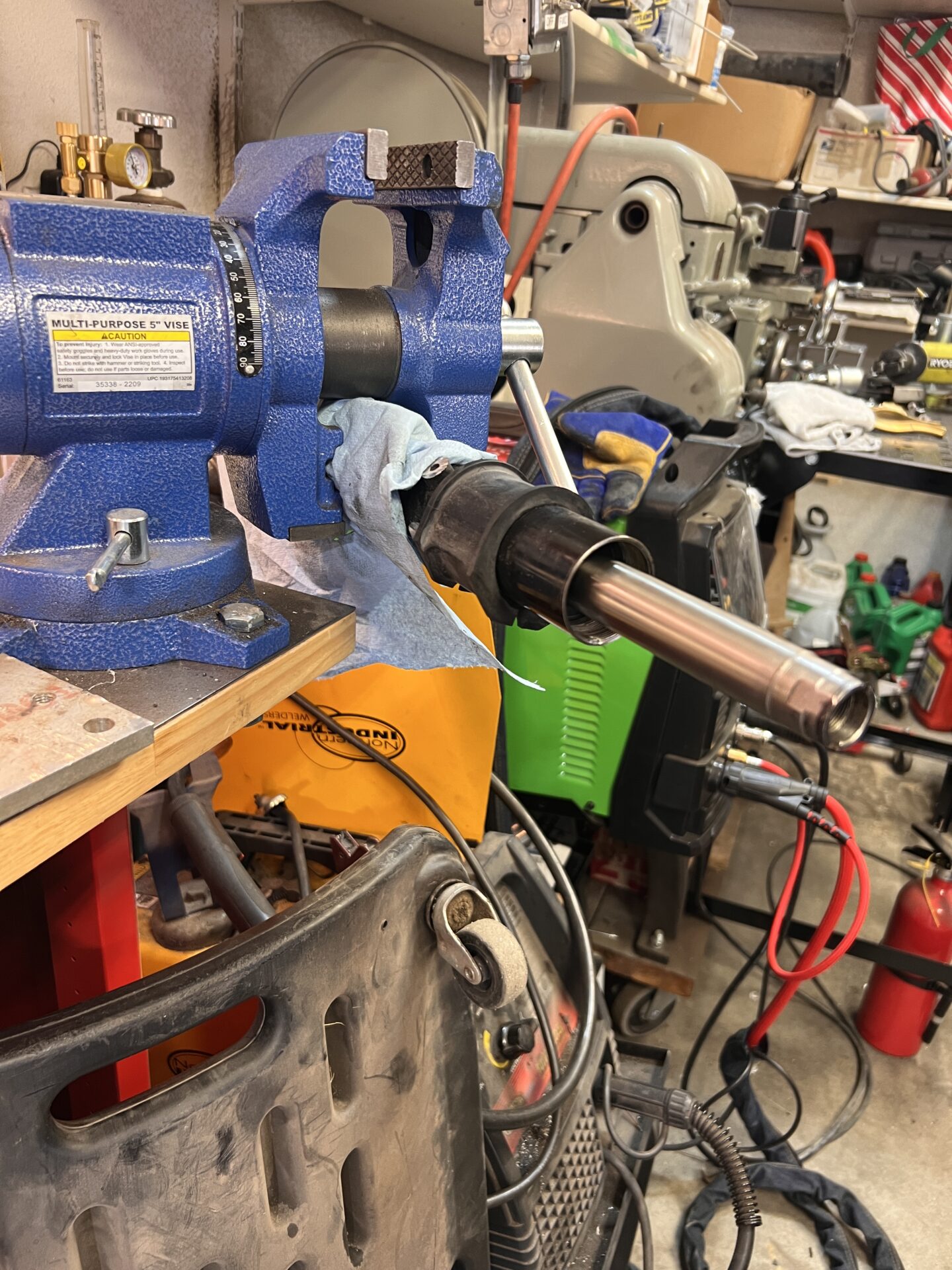

Once that cap is out, there's a seal buried a couple inches in the rack, but there was no retention of the seal and no obvious way to pull it without damaging it, so I started trying to push the bar out against the seal. Unfortunately, the air trapped between the rack seal and that seal made a really nice spring so any attempt to hit it with a deadblow was just little hammering a spring - it would bounce back but wouldn't move out at all. I tried using a ratchet strap to put tension on it, but that wasn't even enough.

I keep the hydraulic press in the basement utility room so that a rarely-used bulky tool doesn't waste space in the garage. Coincidentally, the sprinkler shutoff is also in that utility room so I had to wait until the sprinkler guy was done. In the meantime I used a coupling nut and M6 bolt to raise the radiator up about an inch to give me better clearance over the rack:

I'm gaining confidence in aluminum welding, so I may end up just moving the lower radiator connection out of the way of the rack and maybe in a better place for this engine. Once the sprinkler guy took off I went and pressed the shaft out.

And here's the offending seal that needs removed to actually accomplish the "depower."

I used the angle grinder to cut alllmost all of the way through, then used a chisel (aka large screwdriver...) to break the rest of the way through without nicking the shaft.

Then I got all of the residual grease and fluid and gunk cleaned out of the tube and off of the shaft. I cut all of the extra bosses off of the rack and welded up the two hydraulic ports on the main tube.

At this point everything was ready for reassembly, but I ran out of nitrile gloves and reassembly means slobbing globs of grease all over the whole thing. Don't want to get these soft hands all greasy

. Plus the kids were just about home from school and I had to return the service loaner to pick up my truck.

The service loaner:

Not sure if you're supposed to take the roof and doors off of a loaner but I wasn't not going to do it

Not sure if you're supposed to go offroad in a loaner but I wasn't not going to do it

The 6yo was delighted when I picked her up from school with no roof or doors. We ran home, slammed the doors back on, and drove over to the dealer with no roof (20 minutes on 55mph highways). While I filled up at the gas station I popped the roof panels back on and swapped back to my truck.

The Gladiator might be one of the worst vehicles I've ever driven. The seat was so bad - it felt tilted forward even at the least-tilted setting, I had lower back pain after only 20 minutes in there. The tires were loud, the engine was loud, everything was loud. Well, except for the stereo. At max volume, I still couldn't hear it on the highway with the roof off. The steering wouldn't correct on-center, it liked to wander and drift. The interior was cramped, my head bumped the roll bar and the door strap rubbed on my leg. When my daughter went to climb in she mentioned how tiny it was in the back, too. At low speeds I could feel every lug of the M/T tires individually touching the pavement.

It was shocking getting back into my F-150 - roomier, quieter, smoother, better stereo, way faster, way better mpg...and it's invisible. If you want people to notice you and look and smile and wave then a gray F-150 is not the ticket.

All of that being said, on a day where it's 77 degrees and sunny, there might not be a more fun vehicle to bomb around town in, waving at all of the other Jeep peeps. Kids stared and waved, some guy in a diesel truck made barking noises at me as he passed me, it was great. I can't imagine having to live with this thing every day, but if I'm ever in a place where I can throw away money on a stupid joke that's only usable a fraction of time (he says that and he currently has two racecars...) then maybe...like...a manual 2-door Bronco would be the ticket.