Survey says...yes there's headroom, but it's tiiiiight at the bottom. I'm basically sitting at the injector min effective pulsewidth and idle lambda is about 0.76. The fuel pump and min duty cycle can only get the fuel pressure down to about 160kpa (23psi) so I think I get what I get here.

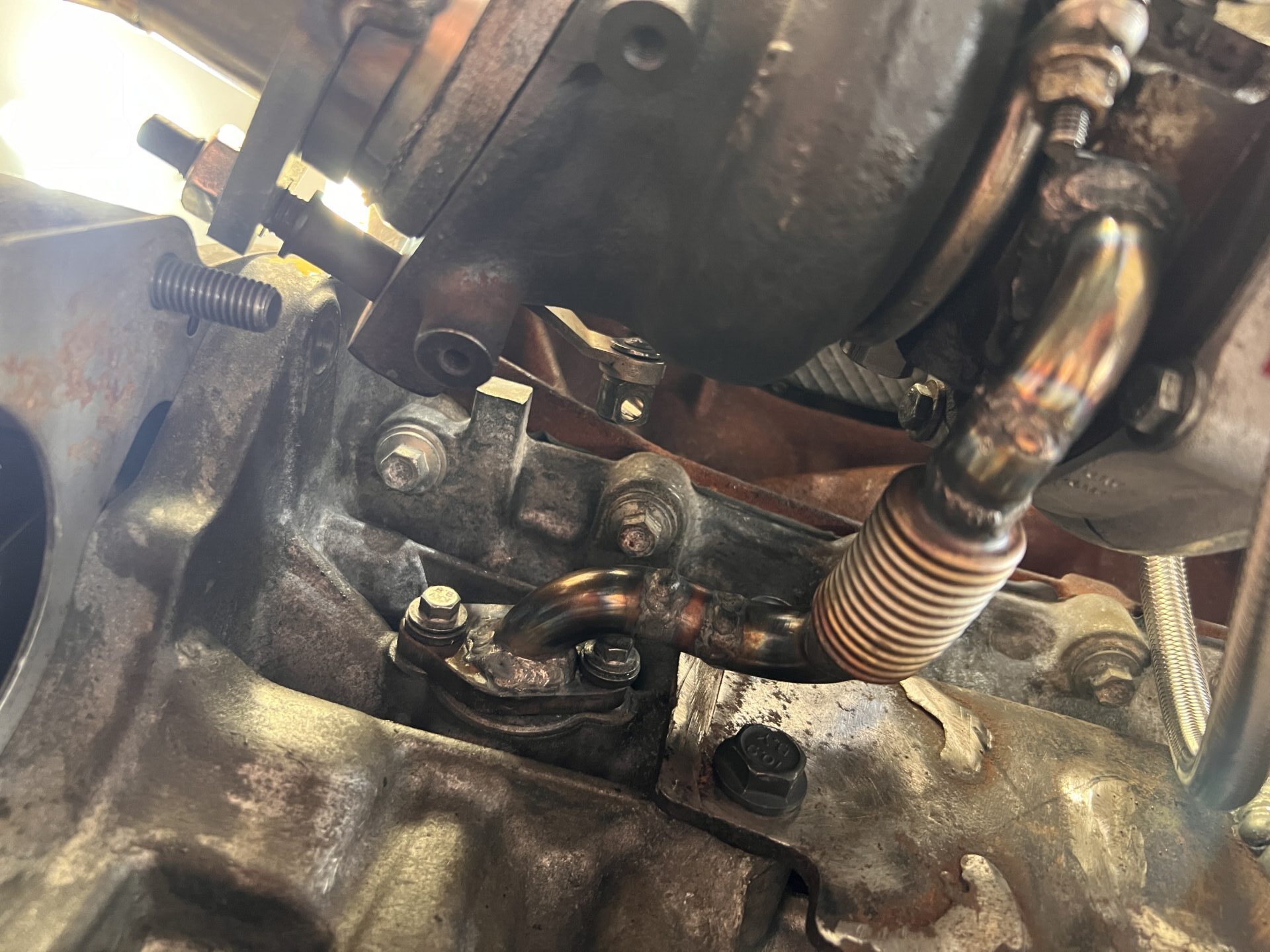

Backing up real quick, I got the oil drains welded up and reinstalled. As a consequence of rotating the drain below the turbo, I can no longer access the bolts that holds the drain in place, which is a T47 torx with a fairly tall head. I ended up swapping that out for a button-head bolt that uses a 4mm hex so I can actually tighten it.

I went to install the other drain tube and as I torqued it up, the coolant fitting started leaking. I must have put just enough stress on that coolant line that it opened up. I pulled the fitting off the back and could see by the rust trail that my welds were not water tight.

I gave that another round of welding, giving me another change to practice TIG and also swearing.

When I bought the button-head screw, I actually grabbed a few different types of the same screw (M6x12mm), one of which was a flange-head bolt with an 8mm head. This coolant connection sits between the turbo and the engine block and there's not enough room to get even a standalone T47 bit in there, so I grabbed the flange-head and it went right in. I double-checked all of my turbo fittings and found that the inner passenger side coolant fitting had no retention bolt at all, it was held in purely by hopes, dreams, and the stiffness of the AN hose. With that done, I topped off the water and went for another start.

On the first startup, I was only seeing about 80kPa (11psi) of fuel pressure. Weird, but the Link accommodated and the engine ran fine. After a bit I pulled the fuel pump from the tank and found that the hose had burst right after the fuel pump, so most of the flow was bypassing the hose. I'm not sure this hose is submersion-rated

. I cut off that last inch, reinstalled the hose, and we were back to normal.

I poked at the fuel and ignition tables a bit, but mostly I wanted to test boost control. Happy to say it works - at idle, the vacuum pump can easily open or close the wastegates via the boost control solenoid.

https://www.youtube.com/shorts/GSwWevC3TQ4Startup is still 50/50, I posted a couple of trigger logs to the Link forums to see if we can nail that down. But when it starts, it settles down to idle very nicely. I fiddled with the oil pressure control a bit in hopes that it would spike to 90+psi when it doesn't need to, some small improvements there.

After I shut down I checked the oil drains and both are still seeping oil.

So another pull, leak check, and re-seal.

Other than that, the next step is to get the passenger side wastegate mounted up. The driver's side will have to wait until the engine is back in the car so I can make sure I'm clearing the steering shaft. I ordered an A/C compressor from Summit as the next time the engine is back in the car I'll need to mock that up and make a bracket. The Ford A/C unit is variable displacement and also exists within the Mazda framerail. This new one should be a bit more compact and fit where I need it to. I'll also need to pull the DI fuel pump off and make a blockoff plate for that, and make some preliminary clearance holes in the cowl to get everything to fit. I'm taking next week off of work, it would be super neato if I could get the engine running in the car, but we'll see how things go.