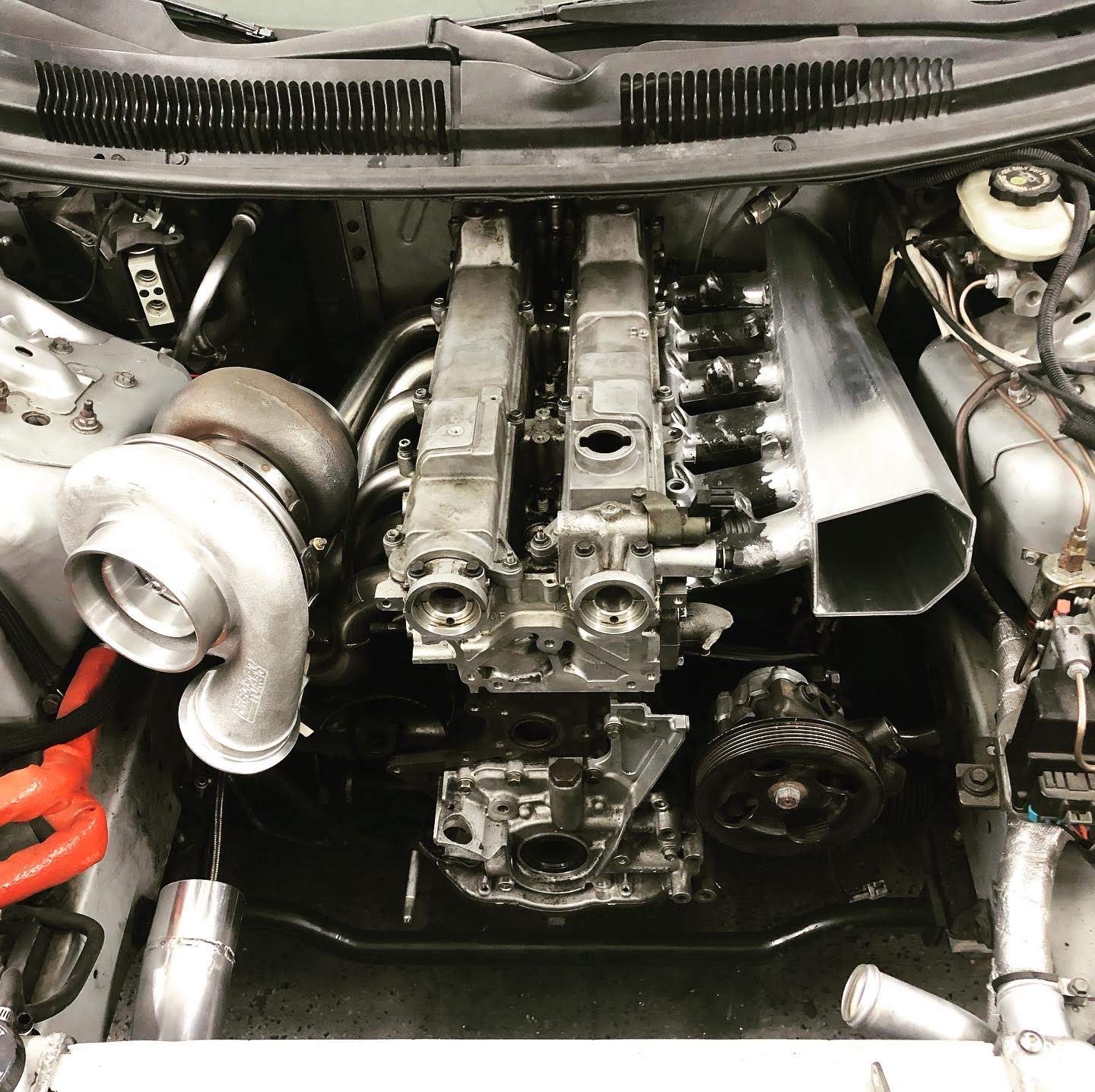

Intake manifold fabricobblation:

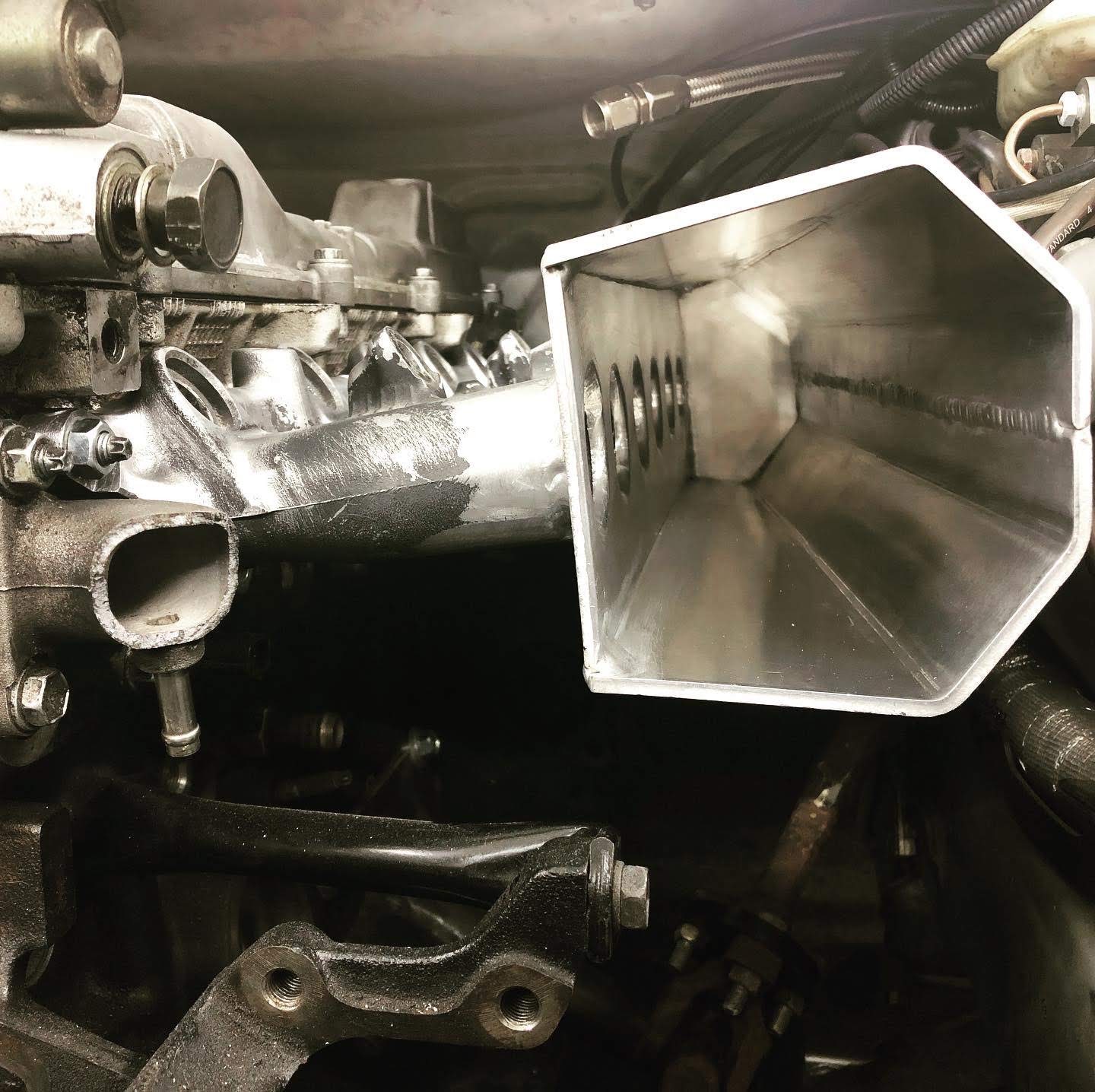

This was a real PITA, and the most complex thing I've ever fabricated I think. I cut the runners off flush, about 1.5" shorter than stock. I then marked the runners on a 3/16 flat plate (3003) and cut them with a step bit to "big but not all the big" then welded the runners to the plate (this was a real PITA, between snaking the torch around them and welding old dirty cast to the 3003. Anyway, once that was done, I used a wood router with a 1/4" roundover bit to enlarge the holes to proper size and bellmouth them. I cleaned that up with a die grinder a bit here and there.

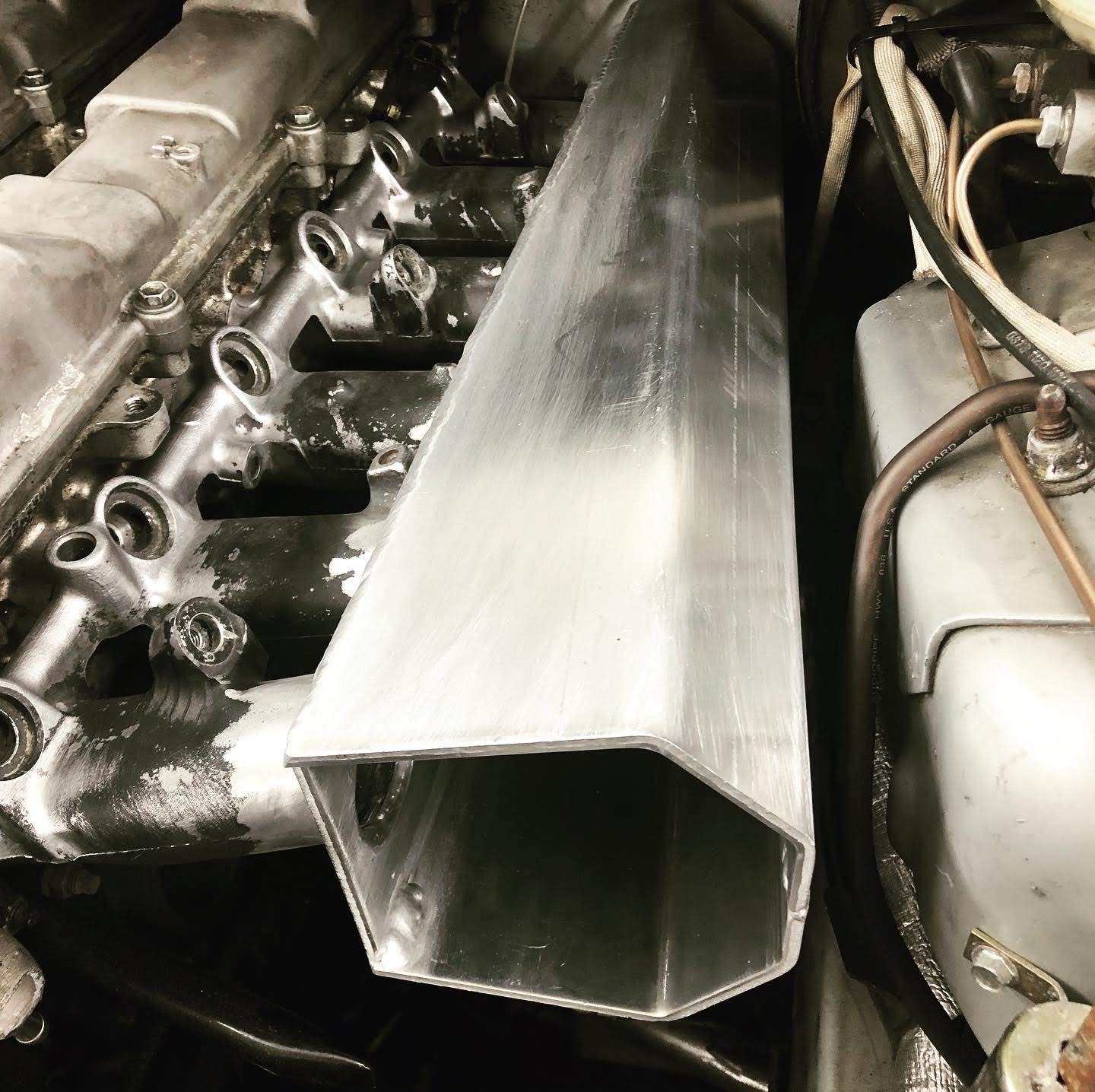

On the plenum, I bent up some more 3/16" plate to try and get as much volume as I could from the area, while dodging strut tower and brake booster. I ended up with the shape you see there. I had to do it in two pieces to fit in my press brake, so I welded the joint from the inside and outside (which were both chamfered for better penetration). The layout was also done to try and maximize strength in the intake (same reason I did it with 3/16")

I then cut everything to fit and seam welded all of it. The corners were all set to have a very small overlap of about 1/16" so that a good bit of the edges were exposed to be sure that the welds got good, consistent penetration.

All that's left will be to pick up an LS throttle body flange (using a GM 90mm "gold blade" on the car) and fabricate an adapter plate for that. I will also add a doubler plate on the bottom in an area to add strength for tapping NPT ports for vacuum, etc. I may also add a couple standoffs to the bottom to mount up a vacuum manifold block so that's it nicely integrated into the package.

It's not perfect but for a first attempt at something like this, I'm pretty pleased with it, and most importantly it fits and (probably) won't explode when we boost it.