Long time listener, first time caller.

After asking many questions and sucking resources from others, I thought it was about time that I gave back and let you have a look at what I am up to.

In 2011 I imported this 1997 FD from Japan. Importing meant that I could save between 5-7 thousand over buying local. The downside however, my dealer- who visibly inspected the car- had no idea what he was supposed to be looking for. The continual low coolant buzzer should have been enough, but common sense is apparently not that.

A quick champagne test was all that was needed. Water seals- gone. Young being dumb, I upped the boost and dropped the rear rotor within a week of owning it. I bought the car to do the conversion any who so wasn't too worried.

After puling the motor and selling, the big save began. Six months without the car on the road and I had decided it was going to take too long to complete and dropped an imported 13b back into the chassis. Running the turbos non-sequential with new plugs, filters etc. the car ran well for 3 months. A track day was the unpinning of it.

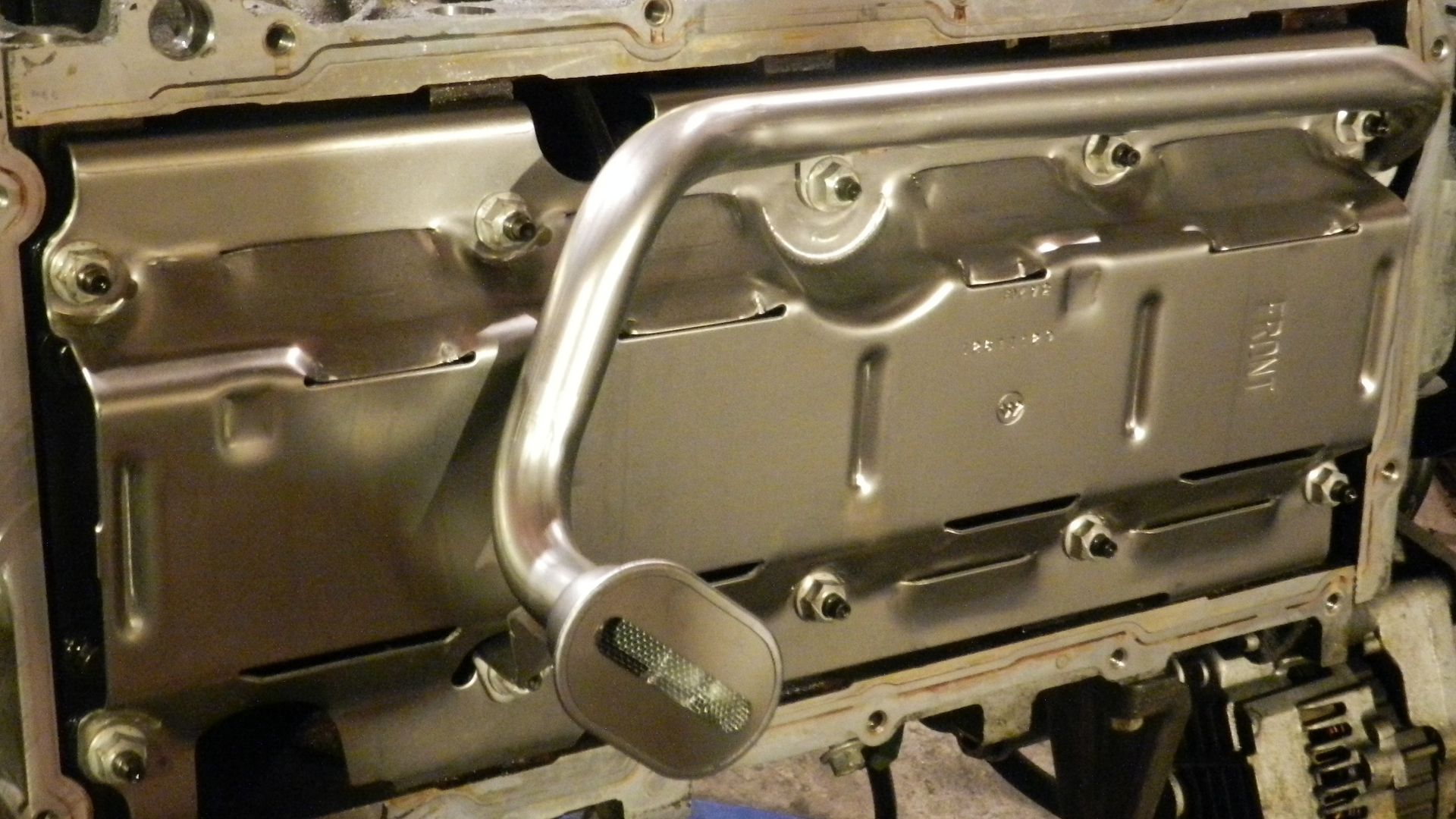

Trying to flat shift into 4th resulted in losing compression in the rear housing. A wasted exercise. Pulling the motor and selling was logical and the save begun (again). This time, the funds from the sale of this and other rotard-ry gear went straight into a 2003 LS6. Later in the year, a relatively cheap T56 came up from an 04 GTO (equivalent).

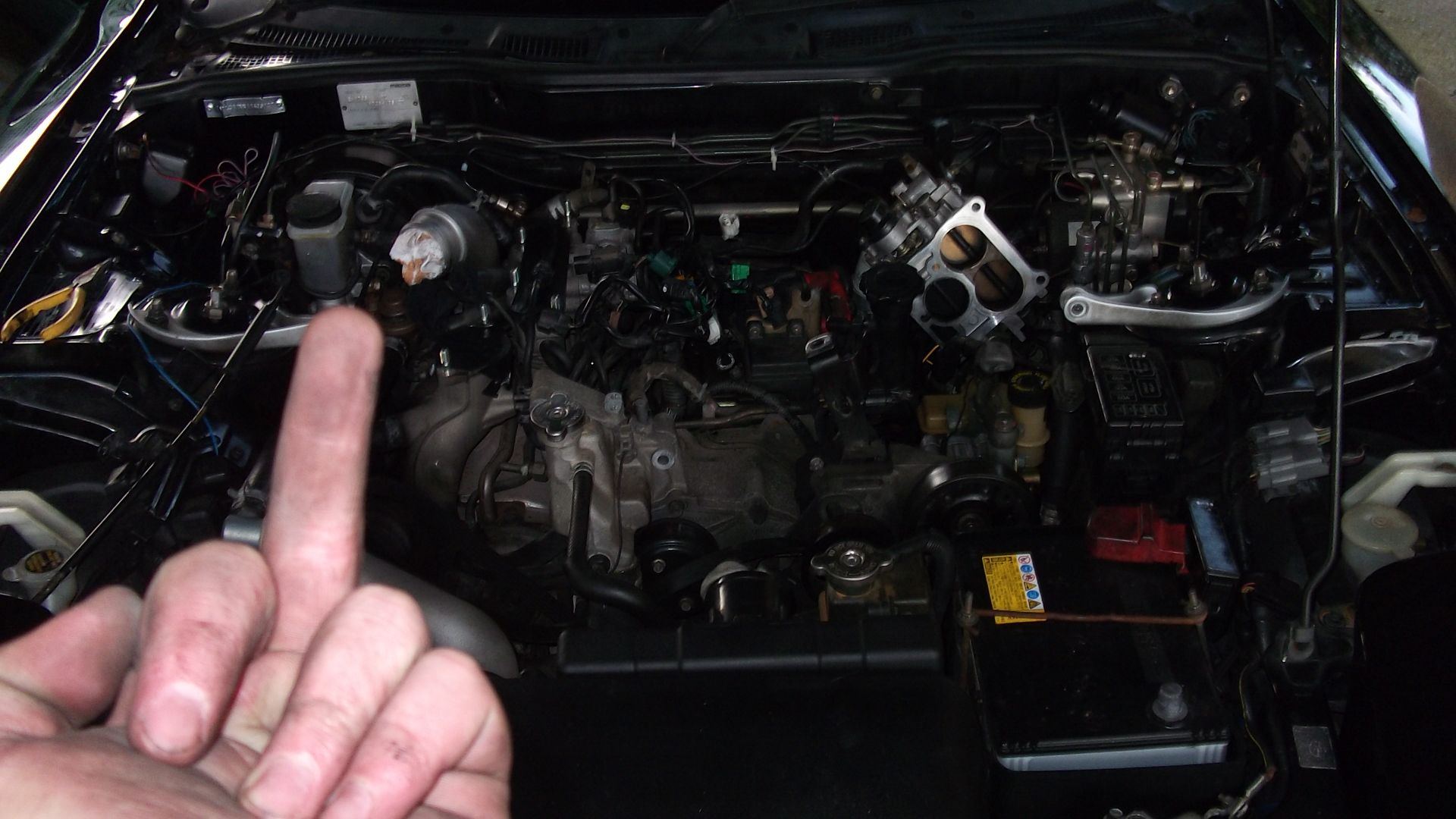

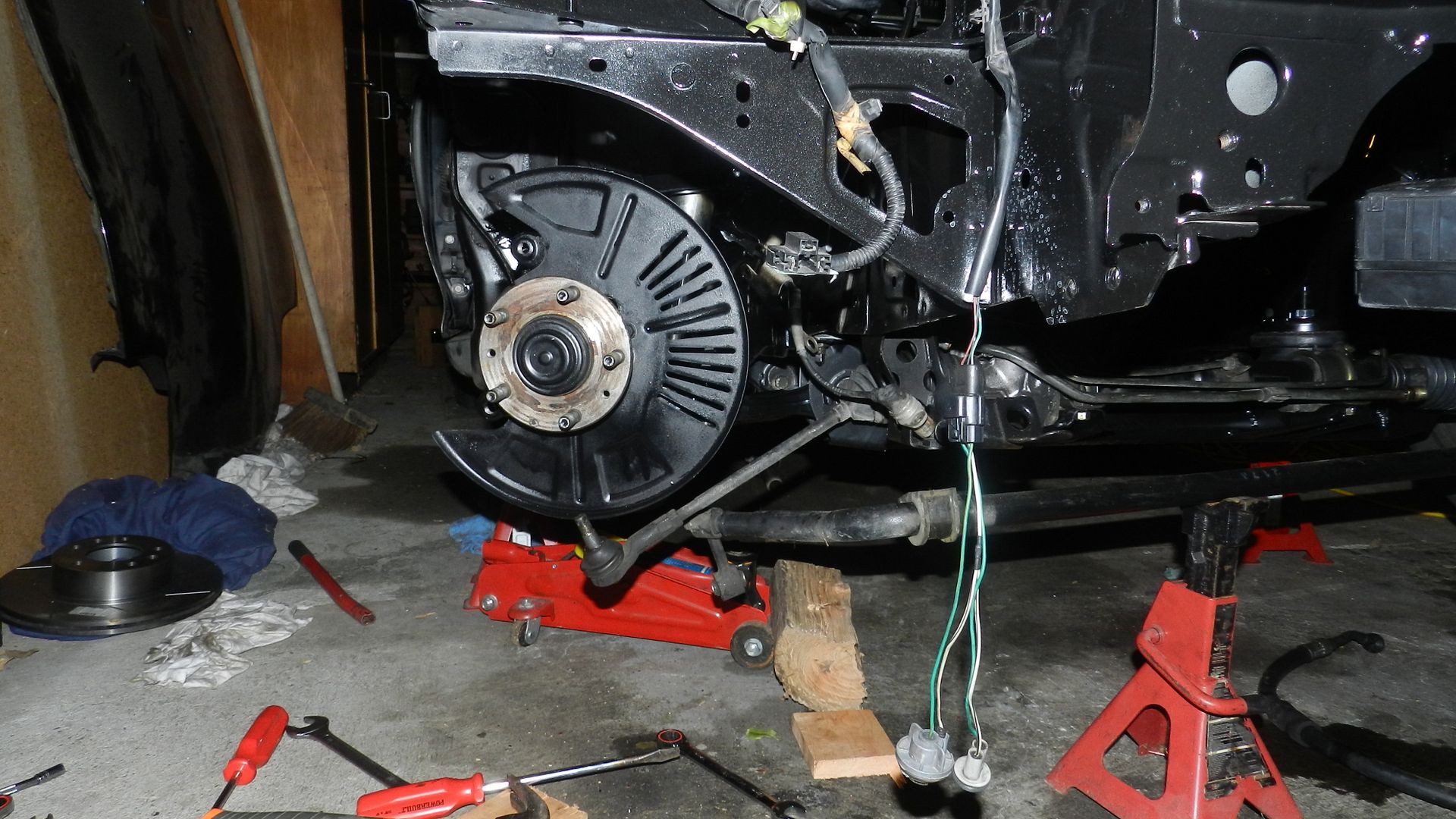

In waiting for cash flow, a few free and easy jobs were done in order to tidy things up. The engine bay was painted and suspension arms cleaned up. New brake rotors and pads were brought for the front and rear.

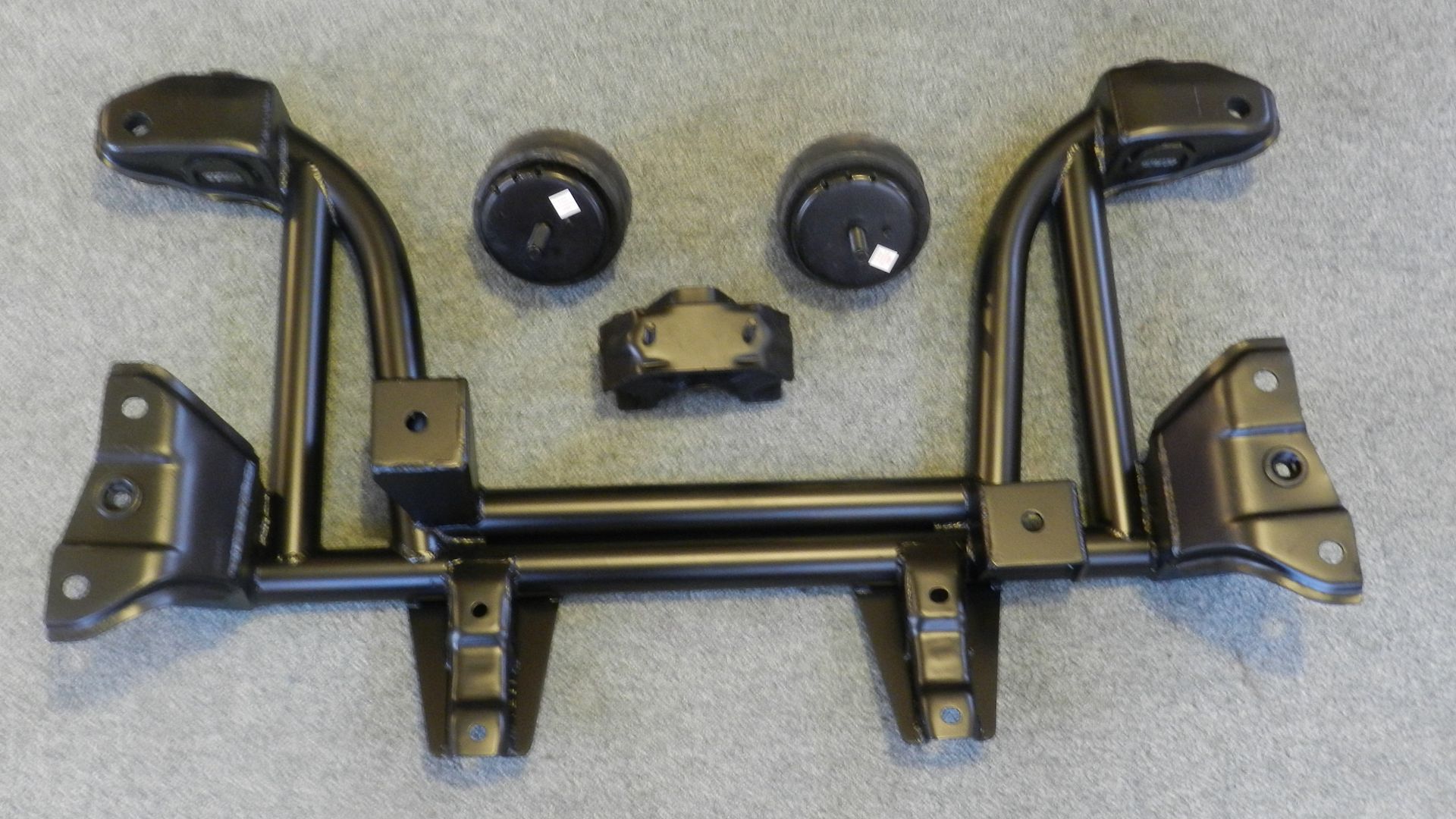

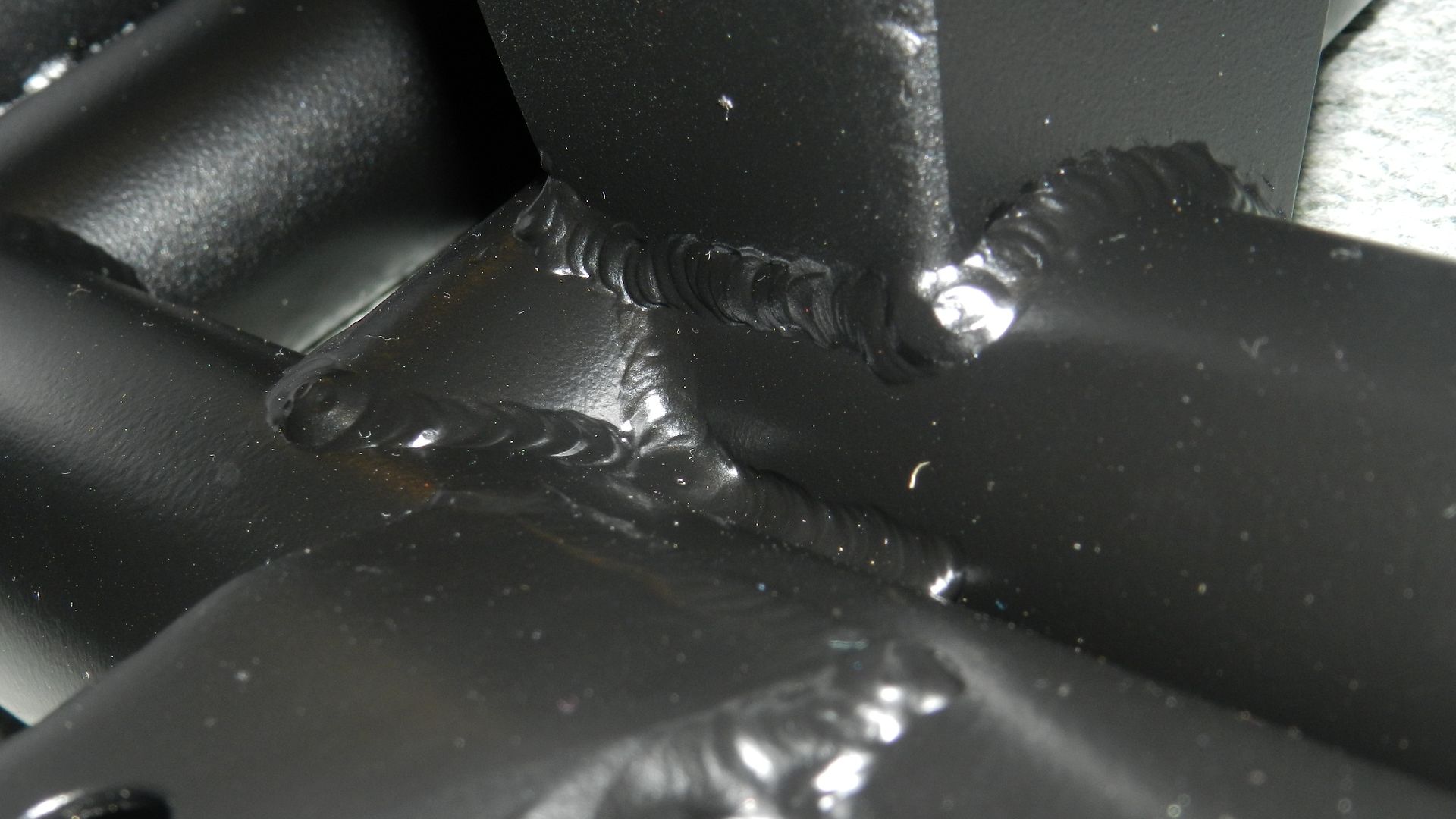

A local man had already converted an FD for drifting and had made a jig for the subframe. An exchange of cash and the factory subframe resulted in an easy bolt in solution that utilised factory mounts. One difference to Samberg is that this frame uses the front mounting points on the engine in order to avoid the steering rod. A fabricated engine mount is then needed for the drivers side.