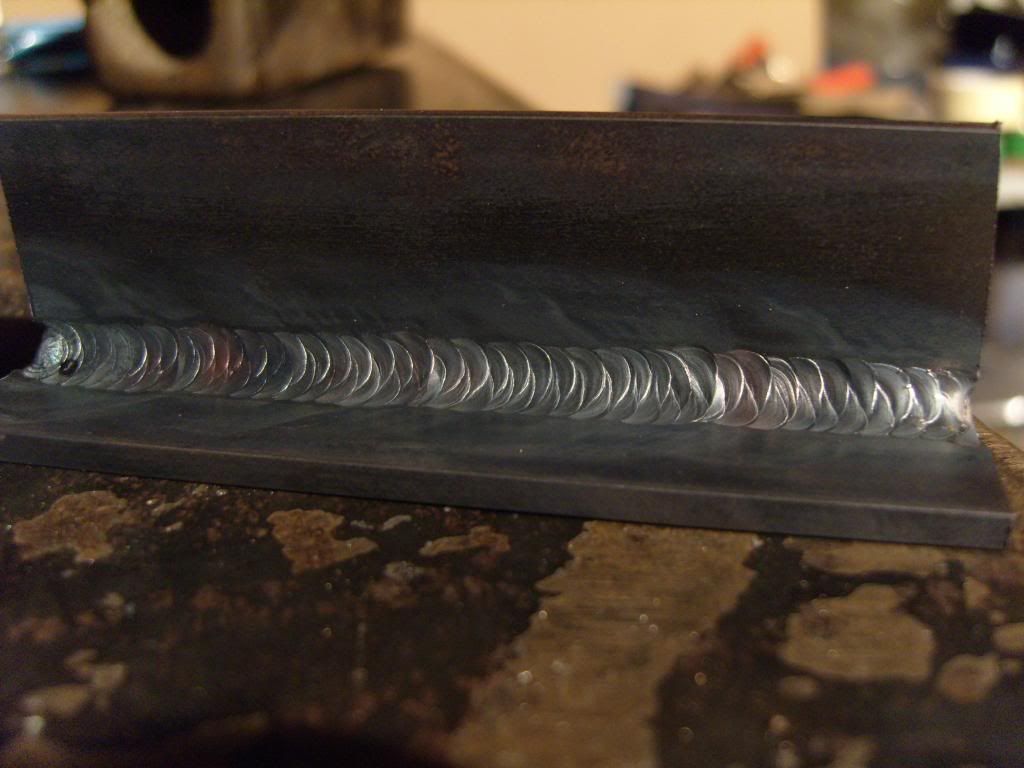

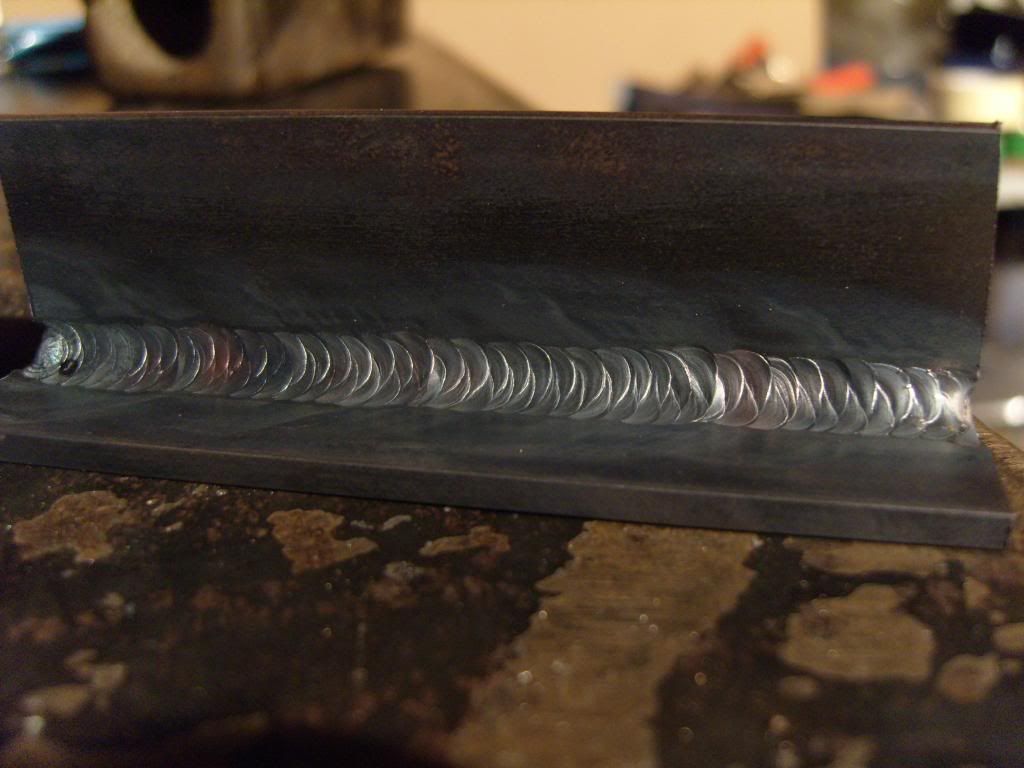

did some more aluminum drills since i haven't in awhile, progress feels good, I'm up to over 140amps on 1/8th aluminum now which even feels more natural. I probably did 10 tee joints today and never dipped my tungsten once, which is a miracle to me since i was doing it once or twice a joint when i first started. then i did some multipass+ weave free hand on 1/8th steel. It's amazing the difference in bead width and rod feed from steel to aluminum. when i do the aluminum i probably ram a good 1/2in of 3/32 rod in every dip, on steel it's just a tap of the rod. the first pass on the 1/8th steel is about 3/16, so not much more wider then the material itself. second pass is just a zig zag dipping action. i'm still not comfortable walking the cup or doing laywire yet, but i suppose that will take some serious hood time. doing the t joints on aluminum really helps you get good faster since it forces you to adapt to heat changes, you can see some grain in the end of the aluminum, since the shit heats up quick as hell. do a shit ton of aluminum then switch to steel= cake walk.

didn't even clean off the leaves.

didn't even clean off the leaves.